The world of caviar holds many secrets, but none more intriguing than the distinction between malossol and regular varieties. This traditional term transforms an ancient preservation necessity into a modern luxury standard that defines premium caviar quality. The difference affects taste, texture, price, and health benefits in ways most consumers never realize.

For centuries, caviar enthusiasts have praised the superior taste of malossol varieties without fully understanding the science behind their preference. The distinction between these preparations runs deeper than simple salt content, affecting every aspect from texture to nutritional value. Each method creates entirely different eating experiences from identical sturgeon eggs.

Modern caviar production reveals how traditional techniques evolved into sophisticated preservation methods that prioritize flavor over shelf life. Understanding these distinctions helps appreciate why malossol commands premium prices in luxury markets worldwide. The journey from necessity to artistry tells a fascinating story of culinary evolution.

Salt content levels reveal the surprising difference between malossol and regular caviar

The fundamental distinction between malossol and regular caviar lies in precise salt measurements that dramatically affect the final product. This difference creates two entirely different culinary experiences from identical sturgeon roe. Salt levels determine not only taste but also texture, appearance, and storage requirements.

Traditional preservation methods once required heavy salting to prevent spoilage during transportation across vast distances. Before refrigeration technology, caviar makers had no choice but to use substantial salt quantities to ensure product safety. The harsh conditions of ancient trade routes demanded preservation techniques that prioritized longevity over delicate flavors.

Salt concentration comparison shows the dramatic differences between processing methods:

- Malossol caviar: 2-5% salt content

- Regular caviar: 8-12% salt content

- Traditional payusnaya: 15-20% salt content

- Sea salt varieties: 6-10% salt content

Modern refrigeration changed everything by reducing dependence on salt for preservation. Temperature control allows producers to achieve optimal flavor balance while maintaining product safety. This technological advancement made malossol production possible on a commercial scale.

Malossol contains less than 5% salt while regular caviar may contain 8% or higher

Expert caviar producers define malossol as containing less than 5% salt by weight, with premium varieties often maintaining levels closer to 3%. This precise measurement allows the natural characteristics of sturgeon eggs to remain prominent throughout the curing process. The controlled approach requires exceptional skill and timing.

Regular caviar typically contains 8% salt content or higher, significantly altering both taste and texture compared to lightly salted versions. The increased sodium concentration creates firmer textures while intensifying briny flavors that can overpower subtle nuances. Some varieties reach salt levels as high as 12%.

Modern quality standards recognize malossol as the gold standard for premium caviar products. Professional tasters and connoisseurs consistently prefer the balanced approach that malossol provides. The controlled salt application preserves the delicate membrane structure while preventing excessive dehydration of individual eggs.

Traditional preservation methods required heavy salting before modern refrigeration

Historical caviar production relied exclusively on salt for preservation during long journeys from fishing grounds to markets. Persian and European traders developed various salting techniques to ensure caviar remained edible throughout extended transportation periods. These methods often took weeks or months to complete.

Ancient preservation methods created what became known as “payusnaya caviar,” heavily salted varieties that prioritized shelf life over taste quality. These traditional approaches often masked the natural flavors of different sturgeon species with overwhelming saltiness. The focus remained on survival rather than culinary excellence.

The development of refrigeration technology revolutionized caviar production by reducing dependence on excessive salt for preservation. Modern temperature control allows producers to achieve optimal flavor balance while maintaining product safety. This shift enabled the renaissance of traditional malossol techniques.

Flavor profile transformations that occur during minimal salt processing

Minimal salt processing fundamentally changes how caviar tastes by preserving the natural characteristics that heavy salting would otherwise eliminate. This preservation method creates complex flavor profiles that showcase individual sturgeon species traits. The technique requires precise timing and environmental control to achieve desired results.

The malossol technique allows subtle flavors to develop gradually during the curing process. Light salting enhances natural oils present in sturgeon roe while preventing oxidation that could create off flavors. Temperature controlled environments work together with minimal salt to create optimal conditions for flavor development.

Flavor development stages in malossol processing include specific phases:

- Initial salt application within 30 minutes of extraction

- Primary curing period lasting 24-48 hours

- Flavor maturation phase extending 3-7 days

- Final stabilization before packaging

Each stage contributes unique characteristics to the final flavor profile. The careful timing prevents spoilage while allowing natural compounds to interact properly.

Natural sturgeon roe characteristics remain unmasked in malossol preparation

Malossol preparation preserves the authentic taste profile that each sturgeon species naturally produces. Different varieties of sturgeon create distinct flavor signatures that heavy salting would completely obscure. The gentle approach maintains species identity throughout processing.

Fresh sturgeon roe contains natural oils and proteins that contribute to complex taste experiences. Minimal salt application allows these compounds to interact naturally, creating the signature “pop” and burst of flavor that defines premium caviar. The preservation maintains original cellular structure.

The preservation of natural characteristics enables tasters to distinguish between Beluga, Osetra, and Sevruga varieties based on their unique flavor profiles. Each species maintains its individual personality when processed using malossol techniques. This distinction becomes impossible with heavy salting methods.

Buttery and nutty notes shine through without overwhelming saltiness

Premium malossol caviar develops distinctive buttery textures combined with subtle nutty undertones that create sophisticated taste experiences. These delicate flavors emerge only when salt content remains minimal throughout processing. The natural fats create smooth, creamy sensations.

The creamy consistency of properly prepared malossol caviar allows natural fats to coat the palate smoothly. This texture enhancement works together with reduced saltiness to create luxurious mouthfeel characteristics. The combination produces memorable eating experiences.

Nutty flavor components develop through careful interaction between proteins and natural oils during the curing process. These complex notes distinguish premium caviar from heavily processed alternatives. The subtlety requires trained palates to fully appreciate.

Regular caviar develops more pronounced salty flavors that can mask delicate nuances

Higher salt concentrations in regular caviar create bold, briny flavors that dominate the taste experience. While some consumers enjoy this intensity, it prevents appreciation of subtle flavor variations. The overwhelming saltiness becomes the primary sensation.

Excessive salting draws moisture from sturgeon eggs through osmotic pressure, concentrating flavors but eliminating delicate characteristics. This process creates firmer textures while reducing the natural “pop” that premium caviar provides. The dehydration changes fundamental properties.

Traditional heavily salted varieties often taste similar regardless of sturgeon species because salt overwhelms natural differences. This uniformity reduces the complexity that makes premium caviar so highly valued. The masking effect eliminates terroir distinctions.

Malossol allows individual sturgeon species characteristics to express themselves fully

Each sturgeon species produces roe with unique flavor signatures that malossol processing preserves completely. Beluga caviar maintains its characteristic mild, buttery taste while Osetra develops complex nutty profiles. The gentle processing protects these natural differences.

Species specific characteristics include variations in natural oil content, protein composition, and mineral profiles that create distinct taste experiences. Minimal salt processing ensures these differences remain prominent. The preservation enables true variety appreciation.

Professional caviar tasters rely on these species differences to evaluate quality and authenticity. Malossol preparation makes accurate identification possible by preserving natural characteristics. The skill becomes essential for quality assessment.

Interesting fact: Some caviar experts can identify not only the sturgeon species but also the specific farm or region where malossol caviar was produced, based entirely on subtle flavor variations that minimal salt processing preserves.

Production complexity and technical precision required for authentic malossol curing

Authentic malossol production demands exceptional skill levels and sophisticated equipment that many producers cannot achieve consistently. The delicate balance between preservation and flavor requires expertise developed over generations of traditional craftsmanship. Success depends on precise timing and environmental control.

Temperature control throughout the entire process becomes critical when using minimal salt quantities. Even small variations in storage conditions can affect final product quality significantly. Professional caviar facilities invest heavily in precise environmental controls to maintain optimal curing conditions.

Production requirements for authentic malossol include essential elements:

- Temperature control within 0.5°C tolerance

- Humidity management between 85-95% levels

- Fresh roe processing within 4 hours maximum

- Master craftsman oversight throughout curing

- Quality testing at multiple production stages

Quality control measures for malossol production exceed those required for regular caviar processing. Each batch requires individual assessment to determine optimal salt levels and curing duration. Master craftsmen adjust techniques based on roe characteristics, season, and intended shelf life.

Master craftsman skills developed over generations for perfect salt ratios

Traditional caviar masters spend decades learning to assess roe quality and determine precise salt requirements for each batch. This expertise cannot be replicated through automated processes or standard recipes. The knowledge represents cultural heritage passed down through families.

Professional evaluation includes visual inspection of egg size, color, and membrane integrity before determining salt application methods. Experienced craftsmen recognize subtle variations that affect optimal processing approaches. The assessment requires years of practice to master.

The knowledge transfer process from master to apprentice ensures continuation of traditional techniques that create authentic malossol caviar. These skills represent cultural heritage that modern technology cannot replace. The human element remains irreplaceable.

Temperature controlled environments essential for minimal salt processing success

Modern malossol production requires precise temperature maintenance between 2°C and 2°C throughout the curing process. These narrow temperature ranges prevent spoilage while allowing natural flavor development. The control systems must operate continuously.

Professional facilities use specialized refrigeration systems that maintain consistent temperatures without fluctuation. Temperature variations can cause texture changes or accelerate spoilage in lightly salted products. The equipment requires significant investment.

Humidity control works together with temperature management to create optimal curing environments. Proper atmospheric conditions prevent moisture loss while ensuring adequate preservation. The balance requires constant monitoring.

Interesting fact: The most prestigious caviar houses employ temperature monitoring systems that track conditions every few minutes, as temperature fluctuations of just one degree can affect the final flavor profile of malossol caviar.

Texture and appearance variations between malossol and traditionally salted versions

Physical differences between malossol and regular caviar extend beyond taste to include significant variations in texture, appearance, and structural integrity. These characteristics often provide the first indication of processing methods used. Visual inspection reveals important quality indicators.

Texture variations affect both the eating experience and storage requirements for different caviar types. Understanding these differences helps consumers select appropriate products for specific occasions. The physical properties influence culinary applications.

| Characteristic | Malossol Caviar | Regular Caviar |

|---|---|---|

| Texture | Soft, delicate pop | Firm, chewy consistency |

| Color | Natural, glossy appearance | Darker, concentrated hues |

| Membrane | Intact, flexible structure | Hardened, brittle shell |

| Moisture | High natural content | Reduced through osmosis |

| Shelf Life | 10-14 days opened | 4-6 weeks opened |

Visual inspection reveals important quality indicators that distinguish premium malossol varieties from heavily salted alternatives. Color intensity, membrane clarity, and overall appearance reflect processing techniques and final product quality. The differences become apparent to trained observers.

Osmotic properties create firmer texture in heavily salted regular caviar

Higher salt concentrations draw moisture from sturgeon eggs through osmotic pressure, creating firmer textures that some consumers prefer. This dehydration process concentrates flavors while changing the original egg structure. The transformation affects eating experience significantly.

Salted caviar develops increased resistance to pressure, making individual eggs less likely to burst during handling. Professional chefs sometimes prefer this durability for certain culinary applications. The firmness provides practical advantages in commercial settings.

The osmotic effect also reduces the natural “pop” sensation that characterizes premium caviar. Heavily salted varieties provide different textural experiences compared to minimally processed alternatives. The change affects consumer expectations and preferences.

Malossol maintains softer consistency preserving original roe structure

Minimal salt processing preserves the natural moisture content of sturgeon eggs, maintaining their original soft consistency. This texture allows individual eggs to burst easily on the palate, releasing concentrated flavors. The preservation maintains authentic characteristics.

The preserved roe structure creates the characteristic “pop” that defines premium caviar experiences. Each egg maintains its individual integrity while providing smooth, creamy textures. The sensation becomes a quality indicator for consumers.

Softer consistency requires more careful handling and storage compared to firmer, heavily salted varieties. This delicate nature contributes to the premium positioning of malossol products. The fragility demands specialized handling procedures.

Color intensity differences emerge based on salt concentration levels

Salt concentration affects the visual appearance of caviar through changes in light reflection and color saturation. Malossol varieties typically maintain more natural coloration compared to heavily processed alternatives. The preservation maintains authentic appearance.

Higher salt content can darken caviar colors through dehydration effects that concentrate pigments. This intensification sometimes creates artificial appearance characteristics that differ from natural roe colors. The change affects visual appeal and authenticity.

Premium malossol caviar displays glossy appearances with clear color definition that reflects proper processing techniques. Visual quality indicators help identify authentic products. The appearance becomes a authentication method.

Membrane integrity stays intact longer in lightly salted preparations

Minimal salt processing preserves the natural strength of egg membranes, extending storage life while maintaining texture quality. Well preserved membranes prevent premature bursting during handling. The integrity ensures consistent quality throughout shelf life.

Properly maintained membrane integrity ensures consistent texture experiences throughout the product’s shelf life. Damaged membranes create mushy textures that indicate poor processing or storage. The preservation requires careful handling throughout production.

The preservation of membrane structure contributes to the overall eating experience by maintaining individual egg definition. Premium caviar requires intact membranes for proper texture. The structural integrity becomes essential for quality.

Interesting fact: Expert caviar evaluators can determine the approximate salt content and processing method by gently pressing individual eggs and observing how quickly they burst, with malossol varieties providing noticeably different resistance patterns.

Price premiums and market positioning factors that distinguish malossol products

Malossol caviar commands significantly higher prices than regular varieties due to increased production costs and superior quality characteristics. Market positioning reflects both the technical complexity of production and consumer demand for premium products. The pricing reflects true production costs and quality differences.

The luxury market recognizes malossol as the standard for premium caviar quality, creating pricing structures that reflect this positioning. Consumers pay substantial premiums for the enhanced flavor profiles and superior textures that malossol processing provides. The market values authenticity and craftsmanship.

Price factors affecting malossol caviar costs include multiple elements:

- Fresh roe procurement within hours

- Master craftsman labor requirements

- Specialized temperature control equipment

- Shorter shelf life reducing inventory turnover

- Premium distribution channel requirements

Distribution channels for malossol products require specialized handling capabilities that increase overall costs. Temperature control, rapid transportation, and proper storage facilities add to the final retail price. The infrastructure requirements limit market access.

Higher production costs due to fresher roe requirements and careful processing

Malossol production requires extremely fresh roe that must be processed within hours of extraction to achieve optimal results. This freshness requirement increases sourcing costs and limits production scheduling flexibility. The timing constraints affect operational efficiency.

The careful processing techniques needed for malossol create higher labor costs compared to standard caviar production. Skilled craftsmen command premium wages for their expertise in traditional methods. The human element cannot be replaced by automation.

Quality control measures for malossol production require additional testing and evaluation procedures that increase overall processing costs. Each batch needs individual assessment to ensure proper salt content and curing. The attention to detail demands additional resources.

Shorter shelf life demands premium distribution channels and handling

Malossol caviar typically maintains peak quality for shorter periods compared to heavily salted varieties, requiring faster distribution and specialized storage facilities. This urgency increases logistics costs significantly. The time pressure affects entire supply chains.

Premium retailers invest in specialized refrigeration equipment to maintain proper storage temperatures for malossol products. These infrastructure requirements limit distribution networks and increase handling costs. The investment barriers restrict market access.

The shortened shelf life creates inventory management challenges that affect pricing throughout the supply chain. Retailers must balance quality maintenance with inventory turnover rates. The complexity adds operational costs throughout distribution.

Interesting fact: The most exclusive malossol caviar varieties have shelf lives as short as 10-14 days after opening, compared to several months for heavily salted traditional varieties, explaining the premium pricing structure of these exceptional products.

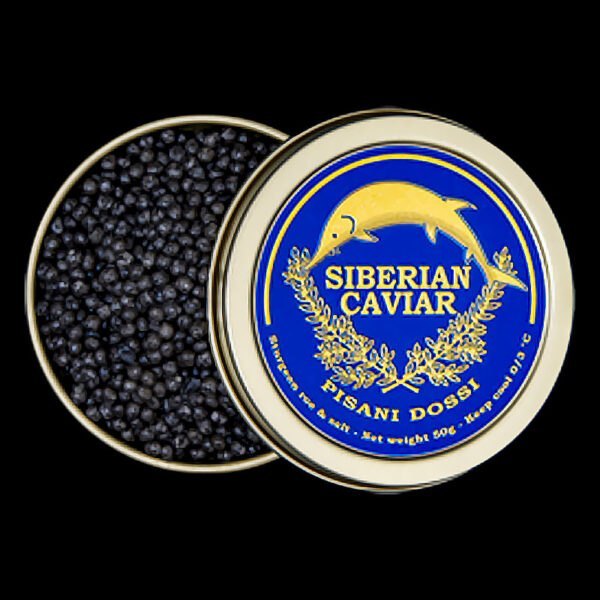

Premium fresh black caviar without preservatives at PremiumCaviar Shop

PremiumCaviar specializes in exceptional black caviar varieties sourced from sustainable Italian aquaculture. The company delivers fresh caviar without artificial preservatives or additives through traditional malossol processing methods. Each product maintains authentic flavor profiles while supporting environmentally responsible farming practices.

The shop features premium selections from the prestigious Pisani Dossi farm in northern Italy. This facility operates within a nature reserve using pure spring water for optimal sturgeon breeding conditions. Traditional hand processing techniques ensure superior quality while preserving delicate textures and natural taste characteristics.

Premium Siberian sturgeon caviar excellence

Siberian sturgeon caviar represents the finest expression of Italian aquaculture craftsmanship. The variety features fine-grained texture with eggs measuring 2.6 to 3.0 mm in consistent black to grey coloration. Each batch delivers pure, elegant flavors beginning with mild initial notes developing into subtle hazelnut undertones.

Wild berry hints create a balanced flavor journey with exquisite length remaining both fine and clear. The sophisticated taste experience lingers pleasantly without harsh aftertaste. Traditional malossol methods using 3.5 to 4% salt content preserve natural characteristics while ensuring proper preservation.

Hand processing throughout every stage maintains grain integrity without mechanical intervention. Workers carefully sort eggs according to size, color, and firmness standards. Vacuum-sealed packaging maintains freshness naturally while providing complete traceability from farm to table.

Premium Siberian Sturgeon Black Caviar

Premium Siberian Sturgeon fresh black caviar 50gr. Pisani Dossi

Premium Siberian Sturgeon fresh black caviar 100gr. Pisani Dossi

Premium Osetra black caviar distinction

Osetra caviar features larger grains measuring 2.9 to 3.2 mm with distinctive mild taste and slight walnut aftertaste. This variety comes from hybrid sturgeon crossing Russian and Siberian species to create unique flavor profiles. Colors vary dramatically from pearl grey to bronze and amber hues.

The hybrid breeding program creates characteristics unavailable in pure species alone. Enhanced robustness and superior egg quality result from carefully selected genetic traits. Seasonal production occurs mainly from October to March, creating limited availability that contributes to exclusivity.

Each female sturgeon undergoes careful daily monitoring with processing timed precisely for peak quality. Only 10 to 20% of females produce caviar-quality eggs, making each batch represent significant investment in time and resources.

Premium Osetra Black Caviar

Premium Osetra fresh black caviar 50gr. Pisani Dossi

Premium Osetra fresh black caviar 100gr. Pisani Dossi

Sustainable company commitment and quality standards

Tovaritch SPIRITS INTERNATIONAL SA operates from Geneva, Switzerland, maintaining strict quality criteria throughout production and distribution. The company upholds green practices in all refined products while ensuring transparency, sustainability, and traceability. No additives, preservatives, or artificial treatments touch any products.

The Pisani Dossi farm began operations in 1982 within a nature reserve established in 1913. Three 40-meter deep wells provide pure water certified as potable by public laboratories. More than 150 temperature-controlled tanks and fifteen earthen ponds create optimal breeding conditions.

Quality control involves meticulous selection of female sturgeon and careful batch monitoring. Each tin contains eggs from a single fish to maintain flavor consistency. Professional specialists handle every step with utmost care to preserve flavor and texture integrity.

Discover exceptional caviar quality and place orders through professional consultation services. Contact the specialist team for personalized recommendations and arrange convenient courier delivery for premium fresh black caviar experiences.

Health benefits and nutritional advantages specific to low salt malossol varieties

Malossol caviar provides significant health advantages through reduced sodium content while preserving beneficial nutrients that heavy salting can compromise. These nutritional benefits contribute to the premium positioning of lightly salted varieties. The health aspects appeal to wellness conscious consumers.

The preservation of natural oils and proteins in malossol processing maintains higher levels of beneficial compounds compared to heavily processed alternatives. Minimal salt application allows nutrients to remain in their most bioavailable forms. The gentle processing protects nutritional integrity.

Nutritional advantages of malossol caviar include multiple health benefits:

- Reduced sodium content supporting cardiovascular health

- Preserved omega-3 fatty acids with anti-inflammatory properties

- Intact protein structures maintaining amino acid profiles

- Enhanced vitamin absorption without salt interference

- Natural mineral balance supporting optimal metabolism

Health conscious consumers increasingly seek low sodium alternatives without sacrificing taste quality. Malossol caviar provides an ideal solution for those monitoring salt intake while enjoying luxury foods. The balance satisfies both health and taste requirements.

Reduced sodium intake suitable for health conscious consumers

Malossol caviar contains significantly less sodium than regular varieties, making it suitable for consumers following low salt diets. The 3-5% salt content provides flavor enhancement without excessive sodium levels. The reduction supports various health goals.

Medical professionals often recommend limiting sodium intake to reduce cardiovascular disease risks. Malossol varieties allow caviar enjoyment while maintaining dietary restrictions. The lower sodium content supports heart health without sacrifice.

The natural flavor preservation in malossol processing means consumers can enjoy full taste experiences with reduced salt consumption. This balance appeals to health conscious luxury food enthusiasts. The combination satisfies multiple consumer needs simultaneously.

Better preservation of omega 3 fatty acids and protein integrity

Minimal salt processing preserves the natural omega-3 fatty acid content that provides anti-inflammatory benefits. Heavy salting can alter these beneficial compounds through dehydration and chemical changes. The gentle approach maintains nutritional value.

Protein structures remain intact during gentle malossol curing, maintaining their nutritional value and bioavailability. This preservation ensures maximum health benefits from caviar consumption. The proteins retain their complete amino acid profiles.

The natural amino acid profiles of sturgeon roe stay complete in malossol varieties, providing essential nutrients in their most usable forms. These compounds support various bodily functions. The preservation maintains nutritional completeness.

Enhanced vitamin and mineral bioavailability without excessive salt interference

Excessive salt can interfere with the absorption of certain vitamins and minerals present in caviar. Malossol processing maintains optimal mineral balance for better nutrient utilization. The reduced salt content improves nutrient absorption.

Vitamins A, B12, D, and other essential nutrients retain their potency through gentle processing methods. Heavy salting can reduce the bioavailability of these important compounds. The preservation maintains vitamin effectiveness.

The natural mineral content of sturgeon roe includes selenium, iron, and magnesium in forms that the body can easily absorb. Minimal processing preserves these beneficial characteristics. The minerals remain in their most usable forms.

Conclusion

The distinction between malossol and regular caviar represents far more than a simple preference for less salt. This fundamental difference affects every aspect of the caviar experience, from initial appearance through final nutritional benefits. The careful balance achieved through minimal salt processing creates premium products that justify their market positioning through superior quality characteristics.

Understanding these distinctions empowers consumers to make informed choices based on personal preferences and intended uses. Whether seeking the pure flavor expression of malossol varieties or the traditional boldness of heavily salted alternatives, knowledge of processing methods ensures optimal selection for any occasion. The education enables better purchasing decisions.

The evolution from necessity driven preservation to flavor focused artisanal production demonstrates how traditional techniques adapt to modern expectations. Malossol caviar represents the pinnacle of this development, combining centuries of expertise with contemporary quality standards to create truly exceptional luxury products that honor both heritage and innovation.